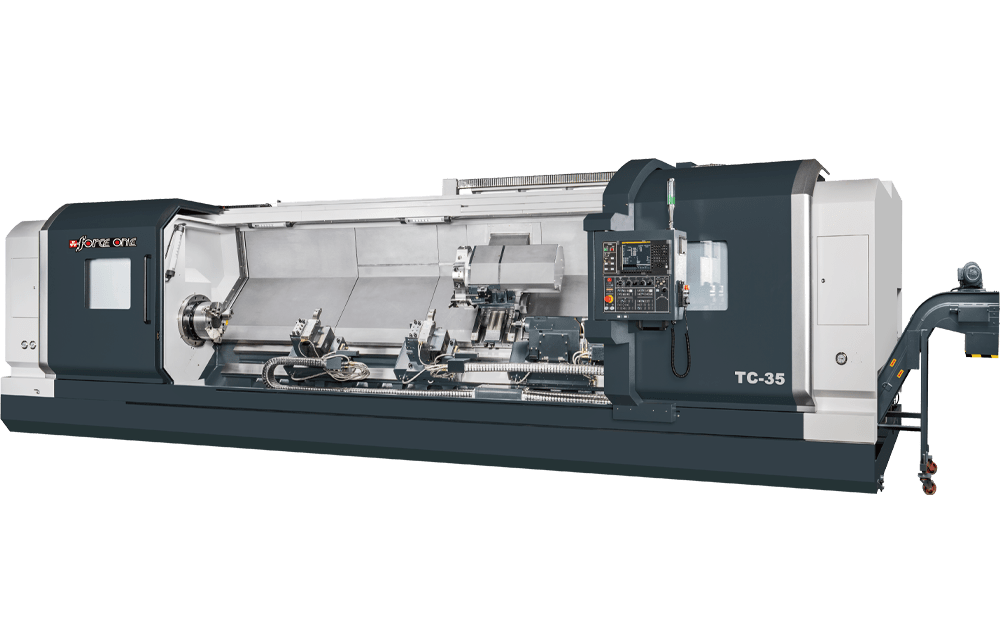

PRECISION CNC SLANT BED LATHE

TC Series

| MODEL | ITEM | UNIT | TC-35L08 | TC-35L15 | TC-35L23 | TC-35L30 | TC-35L40 | TC-35L50 | TC-35L60 | TC-35L70 |

|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Swing over bed | mm(in) | Ø660 (25.98") | |||||||

| Swing over cross slide | mm(in) | Ø480 (18.9") | ||||||||

| Max turning diameter | mm(in) | Ø500 (19.68") | ||||||||

| Spindle nose between center | mm(in) | 943 (37.13") | 1703 (67.0") | 2463 (96.85") | 3223 (126.89") | 4223 (166.26") | 5223 (205.6") | 6223 (245") | 7223(284.37") | |

| Working length | mm(in) | 760 (29.92") | 1520 (59.8") | 2280 (89.76") | 3040 (119.68") | 4040 (159.05") | 5040 (198.42") | 6040 (237.79") | 7040 (277.16") | |

| Spindle | Spindle nose | ISO | STD: A2-8 / OPT: A2-11 | |||||||

| Spindle bore | mm(in) | STD: Ø105 (4.13") / OPT: A2-11: Ø131 (5.15"), Ø165 (6.5") | ||||||||

| Bar capacity | mm(in) | STD: Ø89 (3.5") / OPT: A2-11: Ø117 (4.6"), Ø142 (5.6") | ||||||||

| Max. spindle speed | rpm | STD: 2500 / OPT.: 2000, 1650 | ||||||||

| Spindle gearbox step | 2 | |||||||||

| Living tools speed | rpm | OPT.: 0 ~ 3000 | ||||||||

| Chuck | Hydraulic chuck size | mm(in) | STD.: 12” / OPT.: 15”, 15” | |||||||

| Turret | Station | Station | STD.: 10 / OPT.: 12 | |||||||

| O.D. tooling | mm(in) | STD.: 32 (1.25") / OPT.: 25 (1") | ||||||||

| I.D. tooling | mm(in) | Ø50 (2") | ||||||||

| X/Z axis | X axis travel | mm(in) | 250+25 (9.84"+1") | |||||||

| Z axis travel | mm(in) | 860 (33.85") | 1620 (63.78") | 2380 (93.7") | 3140 (123.62") | 4140 (163") | 5140 (202.36") | 6140 (241.73") | 7140 (281.10") | |

| Rapid speed (X axis) | m/min | 12 | ||||||||

| Rapid speed (Z axis) | m/min | 15 / 15 / 12 / 8 / 8 / 8 | ||||||||

| Cutting feed rate | mm/min | 0.001 – 500 | ||||||||

| Motor | Spindle (cont. / 30 min.) | kW(HP) | 22 (29.5) / 26 (34.9) | |||||||

| X axis | kW(HP) | 4 (5.3) | ||||||||

| Z axis | kW(HP) | 4 (5.3) | ||||||||

| Hydraulic pump | kW(HP) | 2.2 (3) | ||||||||

| Coolant pump | kW(HP) | 0.75 (1) | ||||||||

| Tailstock | Type | — | Programmable | |||||||

| Tailstock travel | mm(in) | 650 (25.59") | 1410 (55.51") | 2170 (85.43") | 2930 (115.35") | 4930 (194.09") | 5930 (233.46") | 6930 (272.83") | ||

| Quill type | — | STD.: Stable / OPT.: Revolve | ||||||||

| Quill stroke | mm(in) | 100 mm (3.94") | ||||||||

| Quill dia. | mm(in) | Ø110 mm (4.33") | ||||||||

| Taper of center | MT | NO.5 | ||||||||

| Tank capacity | Hydraulic | Litres | 80 | |||||||

| Coolant tank | Litres | 480 | 580 | 680 | 780 | 910 | 1040 | 1170 | 1350 | |

| Dimension | L*W*H | mm | 5304×2130×2235 | 6064×2130×2235 | 6824×2130×2235 | 7584×2130×2235 | 8156×2290×2565 | 9300×2290×2562 | 10325×2290×2562 | 11700×2290×2565 |

| in | 208.8"x83.85"x88" | 238.74"x83.85"x88" | 268.66"x83.85"x88" | 298.42"x83.85"x88" | 320.98"x90.16"x100.98" | 366.14"x90.16"x100.98" | 406.49"x90.16"x100.98" | 460.63"x90.16"x100.98" | ||

| NW/GW | kgs | 10300/11400 | 11300/13610 | 13700/15700 | 16300/18700 | 17500/19200 | 19000/21020 | 21000/23000 | 24500/26500 | |

| *Specifications are subject to change without prior notice | ||||||||||

| MODEL | ITEM | UNIT | TC-40L08 | TC-40L15 | TC-40L23 | TC-40L30 | TC-40L40 | TC-40L50 | TC-40L60 | TC-40L70 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Swing over bed | mm(in) | Ø850 (33.45") | |||||||||

| Swing over cross slide | mm(in) | Ø660 (26") | ||||||||||

| Max turning diameter | mm(in) | Ø710 (27.95") | ||||||||||

| Spindle nose between center | mm(in) | 943 (37.13") | 1703 (67.05") | 2463 (96.85") | 3223 (126.89") | 4223 (166.26") | 5223 (205.63") | 6223 (245") | 7223 (284.37") | |||

| Spindle | Working length | mm(in) | 760 (29.92") | 1520 (59.8") | 2280 (89.76") | 3040 (119.68") | 4040 (159.05") | 5040 (198.42") | 6040 (237.79") | 7040 (277.16") | ||

| Spindle nose | ISO | STD.: A2-8 / OPT.: A2-11 / A2-15 | ||||||||||

| Spindle bore | mm(in) | STD.: Ø105 (4.13") / OPT.: A2-11: Ø131 (5.15"), Ø166 (6.5") / A2-15: Ø180 (7.08") | ||||||||||

| Bar capacity | mm(in) | STD.: Ø89 (3.5") / OPT.: A2-11: Ø117 (4.6"), Ø142 (5.6") / A2-15: Ø166 (6.53") | ||||||||||

| Max. spindle speed | rpm | STD.: 2500 / OPT.: 2000, 1650 / 1300 | ||||||||||

| Spindle gearbox step | 2 | |||||||||||

| Living tools speed | rpm | OPT.: 0 ~ 3000 | ||||||||||

| Chuck | Hydraulic chuck size | mm(in) | STD.: 12" / OPT.: 15", 18" | |||||||||

| Station | Station | STD.: 10 / OPT.: 12 | ||||||||||

| Turret | O.D. tooling | mm(in) | STD.: 32 (1.25") / OPT.: 25 (1") | |||||||||

| I.D. tooling | mm(in) | Ø50 (2") | ||||||||||

| X axis travel | mm(in) | 355+25 (13.97"+1") | ||||||||||

| X/Z axis | Z axis travel | mm(in) | 860 (33.85") | 1620 (63.78") | 2380 (93.7") | 3140 (123.62") | 4140 (163") | 5140 (202.36") | 6140 (241.73") | 7140 (281.10") | ||

| Rapid speed (X axis) | m/min | 12 | ||||||||||

| Rapid speed (Z axis) | m/min | 15 / 15 / 15 / 10 / 8 / 8 / 8 / 8 | ||||||||||

| Cutting feed rate | mm/min | 0.001 ~ 500 | ||||||||||

| Spindle (cont. / 30 min.) | kW(HP) | 22 (29.5) / 26 (34.9) | ||||||||||

| Motor | X axis | kW(HP) | 4 (5.3) | |||||||||

| Z axis | kW(HP) | 4 (5.3) | ||||||||||

| Hydraulic pump | kW(Hp) | 2.2 (3) | ||||||||||

| Coolant pump | kW(Hp) | 0.75 (1) | ||||||||||

| Tailstock | Type | - | Programmable | |||||||||

| Tailstock travel | (mm/in) | 650 (25.59") | 1410 (55.51") | 2170 (85.43") | 2930 (115.35") | 3930 (154.72") | 4930 (194.09") | 5930 (233.46") | 6930 (272.83") | |||

| Quill type | - | STD.: Stable / OPT.: Rvolve | ||||||||||

| Quill stroke | (mm/in) | 100 mm (3.94") | ||||||||||

| Quill dia. | (mm/in) | STD.: Ø110 mm (4.33") / OPT.: Ø160 mm (6.29") | ||||||||||

| Taper of center | MT | NO.5 | ||||||||||

| Tank capacity | Hydraulic | Litres | 80 | |||||||||

| Coolant tank | Litres | 480 | 580 | 680 | 780 | 910 | 1040 | 1170 | 1350 | |||

| Dimension | L*W*H | (mm/in) | 5304x2130x2235 | 6064x2130x2235 | 6824x2130x2235 | 7584x2290x2565 | 8155x2290x2565 | 9300x2290x2565 | 10325x2290x2565 | 11700x2290x2565 | ||

| L*W*H | (mm/in) | 208.81"x83.85"x88" | 238.74"x83.85"x88" | 268.66"x83.85"x88" | 298.58"x90.16"x100.98" | 321.06"x90.16"x100.98" | 366.14"x90.16"x100.98" | 406.5"x90.16"x100.98" | 460.5"x90.16"x100.98" | |||

| NW/GW | (kgs) | 11500/11950 | 12100/13700 | 15600/16800 | 17900/19200 | 19500/21500 | 21200/23000 | 23000/25000 | 26500/28500 | |||

| *Specifications are subject to change without prior notice | ||||||||||||

| MODEL | ITEM | UNIT | TC-50L22 | TC-50L32 | TC-50L42 | TC-50L52 | TC-50L62 | TC-50L72 | |

|---|---|---|---|---|---|---|---|---|---|

| Capacity | Swing over bed | mm(in) | Ø1100 (43") | ||||||

| Swing over cross slide | mm(in) | Ø940 (37") | |||||||

| Max turning diameter | mm(in) | Ø1020 (40") | |||||||

| Spindle nose between center | mm(in) | 2380 (90.7") | 3370 (132.68") | 4300 (169.29") | 5290 (208.27") | 6290 (247.64") | 7290 (287.01") | ||

| Spindle | Working length | mm(in) | 2150 (86.65") | 3140 (123.62") | 4075 (160.43") | 5055 (199.02") | 6055 (238.39") | 7055 (277.76") | |

| Spindle nose | ISO | STD.: A2-11 / OPT.: A2-15 / A2-20 | |||||||

| Spindle bore | mm(in) | STD.: Ø160 (6.3") / OPT.: A2-15: Ø230 (9") / A2-20: Ø320 (12.59"), Ø360 (14.17") | |||||||

| Bar capacity | mm(in) | OPT.: A2-11: Ø142 (5.6"), A2-15: Ø205 (8.07") / A2-20: Deped. On Chuck | |||||||

| Max. spindle speed | rpm | STD.: 1500 / OPT.: 700, 550, 450 | |||||||

| Spindle gearbox step | 4 | ||||||||

| Living tools speed | rpm | OPT.: 0 ~ 3000 | |||||||

| Chuck | Hydraulic chuck size | mm(in) | OPT.: 15"/24"/---, --- | ||||||

| Turret | O.D. tooling | mm(in) | 32 (1.25") | ||||||

| I.D. tooling | mm(in) | Ø50 (2") | |||||||

| X/Z axis | X axis travel | mm(in) | 510±25 (20"+1") | ||||||

| Z axis travel | mm(in) | 2260 (88.97") | 3220 (126.77") | 4090 (161.02") | 5070 (199.61") | 6070 (238.98") | 7070 (278.98") | ||

| Rapid speed (X axis) | m/min | 12 | |||||||

| Rapid speed (Z axis) | m/min | 15 / 10 / 8 / 8 | |||||||

| Cutting feed rate | mm/min | 500 | |||||||

| Motor | Spindle (cont./30 min.) | kW(HP) | 37 (49.6) / 45 (60.3) | ||||||

| X axis | kW(HP) | 4 (5.4) | |||||||

| Z axis | kW(HP) | 7 (9.4) | |||||||

| Coolant | Hydraulic pump | kW(HP) | 3.75 (5) | ||||||

| Coolant pump | kW(HP) | 0.75 (1) | |||||||

| Tailstock | Type | Programmable | |||||||

| Tailstock travel | mm(in) | 1900 (74.8") | 2900 (114.17") | 3900 (153.54") | 4900 (192.91") | 5900 (232.28") | 6900 (271.65") | ||

| Quill type | STD.: Stable / OPT.: Revolve | ||||||||

| Quill stroke | mm(in) | 200 mm (7.87") | |||||||

| Quill dia. | mm(in) | Ø200 mm (7.87") | |||||||

| Taper of center | MT | NO.6 | |||||||

| Tank capacity | Hydraulic | Litres | 80 | ||||||

| Coolant tank | Litres | 670 | 810 | 950 | 1050 | 1150 | 1250 | ||

| Dimension | L*W*H | mm(in) | 8700×3158×3050 | 9700×3318×3380 | 10700×3318×3380 | 11700×3318×3380 | 12700×3393×3455 | 13700×3468×3530 | |

| NW/GW | 342 51'y124 33'x124" | 381.88"×130.63"x133.07" | 421.25'×130.63"x133.07' | 460.62"×130.63^×133.07" | 500"×133 58"×136.02" | 539.37'×136.54"×136.96" | |||

| NW/GW | kgs | 18000/20000 | 23000/27000 | 27000/31000 | 32000/36000 | 37000/41000 | 42000/46000 | ||

| *Specifications are subject to change without prior notice | |||||||||

STANDARD ACCESSORIES

- Spindle oil cooler (TC-45/50)

- 2-stages speed gearbox (TC-35/ 40)

- Three stages speed gear head (TC-45)

- Four stages speed gear head (TC-50)

- Servo turret + 12 stations direct type turret disc

- Manual tailstock + Stable quill + living center (TC-35)

- Programmable tailstoc k+ Stable quill + living center (TC-40/45/50)

- Working lamp

- Heat exchanger of electric box cabinet

- 6 bar coolant pump

- Lubrication system

- Chip conveyor and bucket

- Three color alarm light

- Tool box and tool kits

Optional Accessories

- Larger spindle

- Transformer

- Programmable tailstock + stable quill + living center (TC-35)

- Programmable tailstock + Rotary quill + stable center

(TC-35/40/45/50) - Automatic tool setter

- Cs /Cf axis + power turret

- Larger hydraulic chuck

- 60″ height chip conveyor and bucket

- TS / CE / CSA / UKCA electric control

- Air conditioner for electrical cabinet

- Larger spindle motor

- High pressure coolant pump

- Oil mist collector

- Oil skimmer

- Manual / Hydraulic steady rest

- Sub spindle

STANDARD ACCESSORIES

1. FANUC Control Motors

2. 4” Spindle Bore

3. Auto 4 Steps Spindle Speed Change

4. H4 0r V8 Turret

5. Auto Coolant, Hydraulic and Lubrication System

6. Splash Guard

7. Hydraulic Tailstock

8. Work Light

9. Tool Box with Tools

OPTIONS

1. Extra Spindle Bore and Motor

2. Spindle Oil Chiller

3. Hydraulic / Manual Chuck

4. C Axis or Spindle 1/15 Degree Indexing

5. Driving tool Turret

6. Steady Rest

7. Follow Rest

8. Special Boring Bar Holder

9. Higher Coolant Pressure

10. Chip Conveyor

11. CE Mark

12. Transformer