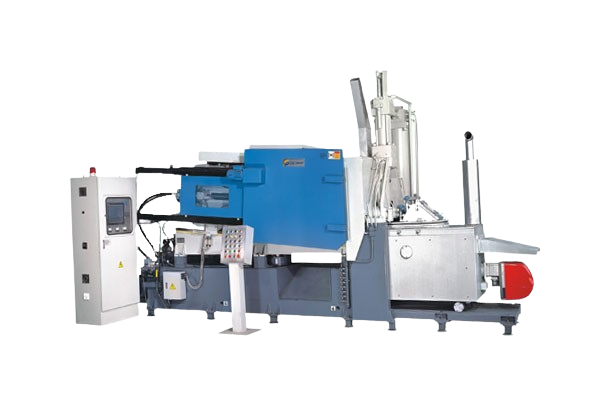

MAGNESIUM HOT CHAMBER DIE CASTING MACHINE

Product details

Control System: The human-computer interface uses touch screen with reliable performance and easy operation, providing the functions of motion simulation, faults self-diagnosis and automatic alarm. Imported encoder is used and the injection curves can be displayed for easy die casting process adjustment.

Plates: High strength cast steel is used in plates and crank shafts, the crank shaft force-expanding mechanism can ensure the reliable mold locking force and rapid mold opening speed. Tie bars are high strength SCM440Cr-plated steel. Electric or hydraulic mold adjustment mechanism is easy for mould replacement.

Hydraulic System: High efficiency cooler is used to cool oil pump with high heat-exchange efficiency and low pressure loss, ensuring the main machine can work continuously under the suitable oil temperature. Hydraulic valves and other hydraulic units of famous Japanese and German brand are used in the pressure and speed control system so that the mechanism can run smoothly, rapidly and safely with energy saving.

Performance Summary:

1、 High integrated control cabinet;

2、 Controlled by industrial PLC system and displayed by color LCD, operating smoothly with strong anti-disturbance;

3、 Digital parameter setting (Pressure, speed proportional valve )

4、 Multiple stage injection control

5、 Through the pressure, flow sensor and the proportional logic valve to realize the continuous control on the speed and the pressure;

6、 Hydraulic, sealing, electrical parts of famous brand. Digital Parameters Setting (double proportional valves);

7、 Optional brake function to reduce the flash of pats and protect the mould.

8、 Machine status display;

9、 Input/Output status display for convenient maintenance;

10、 Saving function for moulds parameter;

11、 The furnace with the protection gas to protect the liquid magnesium efficiently.

STANDARD ACCESSORIES

1. FANUC Control Motors

2. 4” Spindle Bore

3. Auto 4 Steps Spindle Speed Change

4. H4 0r V8 Turret

5. Auto Coolant, Hydraulic and Lubrication System

6. Splash Guard

7. Hydraulic Tailstock

8. Work Light

9. Tool Box with Tools

OPTIONS

1. Extra Spindle Bore and Motor

2. Spindle Oil Chiller

3. Hydraulic / Manual Chuck

4. C Axis or Spindle 1/15 Degree Indexing

5. Driving tool Turret

6. Steady Rest

7. Follow Rest

8. Special Boring Bar Holder

9. Higher Coolant Pressure

10. Chip Conveyor

11. CE Mark

12. Transformer