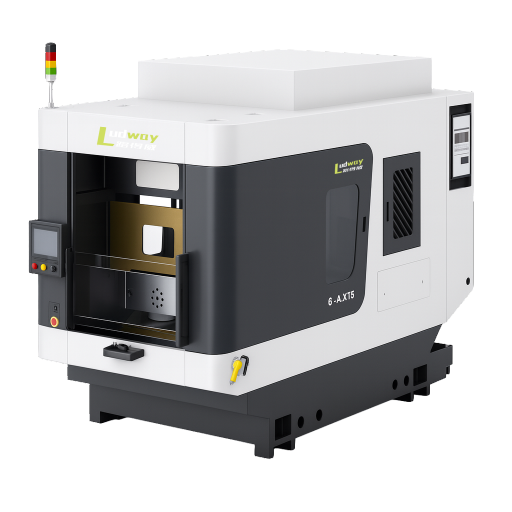

6AXIS DUAL STATION DEBURRING EQUIPMENT

STANDARD ACCESSORIES

1. FANUC Control Motors

2. 4” Spindle Bore

3. Auto 4 Steps Spindle Speed Change

4. H4 0r V8 Turret

5. Auto Coolant, Hydraulic and Lubrication System

6. Splash Guard

7. Hydraulic Tailstock

8. Work Light

9. Tool Box with Tools

OPTIONS

1. Extra Spindle Bore and Motor

2. Spindle Oil Chiller

3. Hydraulic / Manual Chuck

4. C Axis or Spindle 1/15 Degree Indexing

5. Driving tool Turret

6. Steady Rest

7. Follow Rest

8. Special Boring Bar Holder

9. Higher Coolant Pressure

10. Chip Conveyor

11. CE Mark

12. Transformer

LDW-6R-5T-700-2

| MODEL | LDW-6R-5T-700-2 |

|---|---|

| External dimensions | 3570 × 1700 × 2400 mm |

| Equipment itinerary | X700 mm + Y700 mm + Z600 mm |

| Maximum Processing Size | 650 × 600 × 600 mm |

| Air travel speed | 32,000 mm/min |

| Processing speed | 1,000–10,000 mm/min |

| Distance between spindle nose and worktable | 50–550 mm |

| Spindle cooling method | Oil cooling / Air cooling |

| Air pressure demand | ≥ 0.55 MPa |

| Number of spindles | 5 |

| Processing accuracy | ±0.02 mm / 300 mm |

| Drive motor | 1.5 kW × 2 + 4.4 kW + 750 W × 5 |

| Total weight | 5T |

| Control system brand | Xindai |

| Number of Control Axes | 6+2 |

| Spindle power | 1.0 kW – 5.5 kW |

| Spindle speed | 3000 – 24000 RPM |

| Tool clamping range | Φ3 – Φ18 |

| Specifications are subject to change without prior notice | |

• Adopting Taiwan’s (new generation) multi axis control dedicated system.

• Equipped with Taiwan’s (new generation) servo control motor, it has fast response speed, smooth running trajectory, and precise position control.

• Adopting a six axis teaching programming method, multiple specifications of workpieces can be taught and stored;

• Dual station deburring unit, does not occupy the overall rhythm during loading and unloading.

• The spindle can be at any angle, tool change is fast, and there is a starting grinding tool.

• The sports mechanism adopts protective measures and is equipped with an automatic lubrication device;

• Configure a wet chip hopper to facilitate the separation of coolant from chips, achieving recycling and environmental protection.

• The human-machine interface has functions such as real-time display of equipment operating status, production statistics, alarm prompts, and tool usage status.