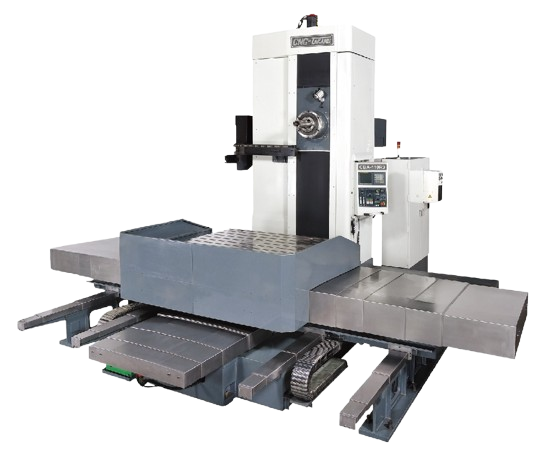

BORING MACHINE

STANDARD ACCESSORIES

1. FANUC Control Motors

2. 4” Spindle Bore

3. Auto 4 Steps Spindle Speed Change

4. H4 0r V8 Turret

5. Auto Coolant, Hydraulic and Lubrication System

6. Splash Guard

7. Hydraulic Tailstock

8. Work Light

9. Tool Box with Tools

OPTIONS

1. Extra Spindle Bore and Motor

2. Spindle Oil Chiller

3. Hydraulic / Manual Chuck

4. C Axis or Spindle 1/15 Degree Indexing

5. Driving tool Turret

6. Steady Rest

7. Follow Rest

8. Special Boring Bar Holder

9. Higher Coolant Pressure

10. Chip Conveyor

11. CE Mark

12. Transformer

CBA Series 2

| T - TYPE | CBA-135TR | CBA-135TR2 | CBA-135TR3 | CBA-135TR4 | |||

| Spindle | Main motor (cont. / 30 min) | kw | AC 37 / 45 | ||||

| Spindle speed (Max.) | rpm | P : 5 - 2000, Q : 5 - 1200 (P : w / o Quill Q : Quill) | |||||

| Spindle tapper | ISO 50 / BT-50 | ||||||

| Spindle diameter | mm | Dia. 135 | |||||

| Spindle end diameter | mm | Dia. 215 | |||||

| Quill diameter (W2) | mm | Dia. 380 (OPT.) | |||||

| Max. spindle torque | Nm | 2150 | |||||

| Travel | Work table travel X axis (Horizontal) | mm | 1500 | 2000 | 3000 | 4000 | |

| Spindle travel Y axis (Vertical) | mm | 1500 | 1800 | 2300 | 2800 | ||

| Column moving travel Z axis | 1100 | 1100 | 1400 | 1700 | |||

| Spindle travel W1 axis | mm | 700 | |||||

| Quill travel W2 axis | mm | 350 | |||||

| Total spindle travel (W1 + W2) | 1050 | ||||||

| Distance from spindle nose to table center | mm | 885 - 1985 | 885 - 1985 | 885 - 2285 | 885 – 2585 | ||

| Distance from spindle center to table surface | mm | 0 - 1500 | 0 - 1800 | 0 - 2300 | 0 - 2800 | ||

| Rotary table | Table dimension | mm | 1250 x 1400 | 1400 x 1600 | 1600 x 1800 | 1800 x 2000 | |

| T-slot | mm x No. | 22 x 7 | 22 x 9 | 22 x 9 | 22 x 9 | ||

| Max. loading weight | kg | 6500 | 8500 | 10000 | 12000 | ||

| Index | degree | 0.001° | |||||

| Max. rotation dimension | mm | 1877 | 2126 | 2408 | 2691 | ||

| Table rotation speed | rpm | 0.8 | |||||

| Feed | Rapid feed | XYZW1 axis | mm / min | XY axis = 8000 / W1 axis = 3000 / Z axis = 5000 | |||

| Feed rate | X / Y / Z axis | mm / min | 1 - 5000 | ||||

| W1 axis | mm / min | 1 - 3000 | |||||

| Quill feed rate | W2 axis | mm / min | 1 - 1500 | ||||

| Power capacity | KVA | 110 | 130 | 130 | 140 | ||

| Machinedimension(LxW xH) | mm | 6750x6950x4700 | 6900x7100x4900 | 7500x7500x5500 | 7850x7850x5950 | ||

| Machine weight | kg | 34500 | 39500 | 45000 | 49000 | ||

| Controller | Fanuc / Siemens / Heidenhain | ||||||

| *Specifications are subject to change without prior notice | |||||||

STANDARD ACCESSORIES

1. FANUC Control Motors

2. 6” Spindle Bore

3. H4 0r V8 Hydraulic Turret

4. Auto Coolant, Hydraulic and Lubrication System

5. Box way on Cross Slide

6. Splash Guard

7. Hydraulic Tailstock with Rotating Quill

8. Chip Conveyors (Auger for front and chain for rear)

9. Work Light

10. Tool Box with Tools

OPTIONS

1. Extra Spindle Bore, Motor and Speeds

2. Spindle Oil Chiller

3. Hydraulic / Manual Chuck

4. Face Plate

5. C Axis or Spindle 5 / 15 degree indexing

6. Y Axis

7. Driving Tool Turret

8. Steady Rest, Follow Rest ( Hydraulic or Manual)

9. Special Boring Bar Holder

10. Heavy Duty Milling Attachment

11. Grinding Head on Turret or Cross Slide

12. Tool Presetter

13. Higher Coolant Pressure

14. Cutting Pass Through Steady Rest Equipment (LC Only)

15. CE Mark

16. Transformer