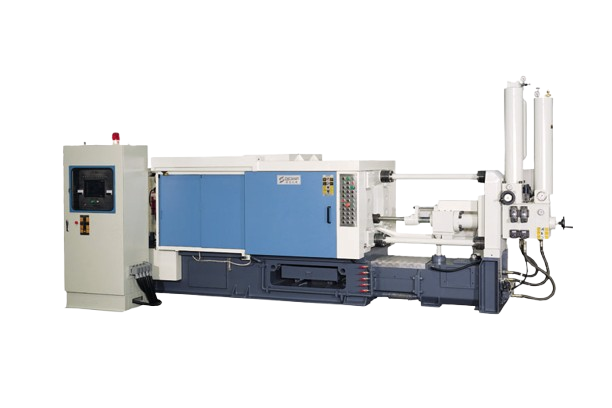

MEDIUM AND SMALL COLD CHAMBER DIE CASTING MACHINE

| No. | Item | Unit | CSC138 | CSC188 | CSC280 | CSC400 | CSC650 | CSC800 | CSC1000 | ||||||||||||||

| 1 | Clamping Force | KN | 1380 | 1880 | 2800 | 4000 | 6500 | 8000 | 10000 | ||||||||||||||

| 2 | Space between Tie Bars | mm | 410X410 | 480X480 | 580X580 | 620X620 | 775X775 | 950X950 | 1030×1030 | ||||||||||||||

| 3 | Die Opening Stroke | mm | 305 | 400 | 470 | 550 | 700 | 800 | 880 | ||||||||||||||

| 4 | Die Height〔min.-max.〕 | mm | 150-450 | 200-550 | 250-650 | 300-700 | 350-880 | 400-950 | 450-1150 | ||||||||||||||

| 5 | Platen Size (H x V) | mm | 620X630 | 730X750 | 900X920 | 970X985 | 1190X1190 | 1400X1400 | 1620×620 | ||||||||||||||

| 6 | Ejector Force | KN | 60 | 76 | 140 | 190 | 300 | 380 | 500 | ||||||||||||||

| 7 | Ejector Stroke | mm | 76 | 100 | 110 | 125 | 150 | 200 | 200 | ||||||||||||||

| 8 | Max. Injection Force | KN | 205 | 233 | 355 | 423 | 650 | 700 | 860 | ||||||||||||||

| 9 | Plunger Stroke | mm | 315 | 350 | 415 | 500 | 620 | 750 | 800 | ||||||||||||||

| 10 | Shot Position | mm | -120 | -125 | -125 | -175 | 0 | -250 | 0 | -250 | 0, -300 | ||||||||||||

| 11 | Plunger Diameter | mm | 40 | 50 | 60 | 40 | 50 | 60 | 50 | 60 | 70 | 60 | 70 | 80 | 70-100 | 80-110 | 90-120 | ||||||

| 12 | Shot Weight | Kg/(Al) | 0.68 | 1 | 1.5 | 0.8 | 1.2 | 1.8 | 1.2 | 2.1 | 2.8 | 2.6 | 3.5 | 4.5 | 4.3-7.3 | 5.5-12.8 | 9.5-16.9 | ||||||

| 13 | Casting Pressure | Mpa | 158 | 102 | 73 | 185 | 118 | 82 | 180 | 125 | 92 | 146 | 109 | 84 | 168-102 | 139-73 | 136-76 | ||||||

| 14 | Casting Area | cm2 | 87 | 135 | 189 | 101 | 158 | 228 | 155 | 224 | 304 | 272 | 364 | 475 | 386-537 | 575-1086 | 730-1305 | ||||||

| 15 | Max. Casting Area (400kg/cm2) | cm2 | 345 | 470 | 700 | 1000 | 1625 | 2000 | 2500 | ||||||||||||||

| 16 | Shot Flange Diameter | mm | 101.6 | 101.6 | 101.6 | 110 | 165 | 200 | 240 | ||||||||||||||

| 17 | Height of Shot Flange | mm | 12 | 12 | 12 | 12 | 15 | 20 | 20 | ||||||||||||||

| 18 | Plunger Penetration | mm | 110 | 120 | 142 | 200 | 250 | 350 | 320 | ||||||||||||||

| 19 | System Working Pressure | Mpa | 12 | 12 | 14 | 14 | 14 | 14 | 16 | ||||||||||||||

| 20 | Motor Capacity | Kw | 15 | 15 | 22 | 22 | 37 | 37 | 45 | ||||||||||||||

| 21 | Oil Tank Capacity | L | 320 | 420 | 600 | 800 | 1000 | 1500 | 1800 | ||||||||||||||

| 23 | Machine Dimension | m | 4.8X1.3X2.5 | 5.5X1.5X2.6 | 5.8X1.6X2.6 | 6.2X1.8X2.8 | 7.8X2.1X2.9 | 8.9X2.5X3.2 | 10.2×3.5×4 | ||||||||||||||

PLC CONTROL UNIT

German Siemens PLC control system with color touch screen provides function as parameters settings & alarm message display, to ensure machine stable, safe and reliable performance.

CLAMPING AND DIE HEIGHT ADJUSTMENT UNIT

High strength and wear resistant casting platens and toggles, toggle system designs with double link tie bar guidance, brings even stress distribution and steady mechanism.

Standard with hydraulic driven gear type die height adjustment for convenient operation & accurate setting.

HYDRAULIC SYSTEM

Hydraulic system adopts a dual proportional control system of pressure and hydraulic flow, achieves multi-stage pressure and speed control, and low pressure clamping protection. European and Japanese made oil seals could enhance machine reliable operation; imported high-low pressure double pump performs lower noise level with high efficiency.

INJECTION UNIT

It adopts with high flow hydraulic system, precision flow control valves and high quality piston accumulators for 2 and 3 stage injection, provides steady injection and individual settings for speed and pressure, injection Unit adopts European design with multi-injection position, enables the maximum transmission of injection force and suitable for variable range of die design.

STANDARD FEATURES

Programmable Logic Controller

Low Pressure Die Closing Protective Program

Proportion Speed & Pressure Control for Die Closing & Opening

Plunger Lubrication System

Centralized Lubrication System

Hydraulic Multi Ejection

Colour Touch Screen Display

Three Stages Injection Speed Control

OPTIONAL FEATURES

1. Servo Drive System

I. Improve machine mechanical efficiency and energy savings.

II. Enhance machine operation precision and speed, thereby further improving the casting quality and cycle time.

III. Effectively reduce the hydraulic oil temperature improve the stability of the machine and prolong the usage life.

IV. Enhanced design suitable to use under metal dust harsh environment, high temperature working conditions.

2. Hydraulic Tie Bar Extraction

3. Core Pulling Device

4. Multi Shot-Position (Hydraulic Lift Up Platform)

5. Automatic Safety Door

6. Injection Monitoring System

7. Die Temperature Monitoring Device

EQUIPMENTS

1. Automatic Ladler

2. Automatic Sprayer

3. Automatic Extractor

4. Trim Press

5. Vacuum Device

STANDARD ACCESSORIES

1. FANUC Control Motors

2. 4” Spindle Bore

3. Auto 4 Steps Spindle Speed Change

4. H4 0r V8 Turret

5. Auto Coolant, Hydraulic and Lubrication System

6. Splash Guard

7. Hydraulic Tailstock

8. Work Light

9. Tool Box with Tools

OPTIONS

1. Extra Spindle Bore and Motor

2. Spindle Oil Chiller

3. Hydraulic / Manual Chuck

4. C Axis or Spindle 1/15 Degree Indexing

5. Driving tool Turret

6. Steady Rest

7. Follow Rest

8. Special Boring Bar Holder

9. Higher Coolant Pressure

10. Chip Conveyor

11. CE Mark

12. Transformer